IADR Abstract Archives

Potential Antibacterial Composite Resin Infused with Hydrated CaO

Objectives: Composite resin is one of the most promising restorative materials today. It is often associated with superior esthetic qualities, ease of use and a conservative approach towards cavity preparation. However, microorganisms accumulate more on the surface of this restoration than other restorative materials which causes secondary caries and eventually leads to failed restorations. The current study aimed to address this drawback by incorporating hydrated calcium oxide (CaO) from calcined Asian moon scallop (Amusium pleuronectes) shells to commercially-available composite resin to produce an antibacterial property.

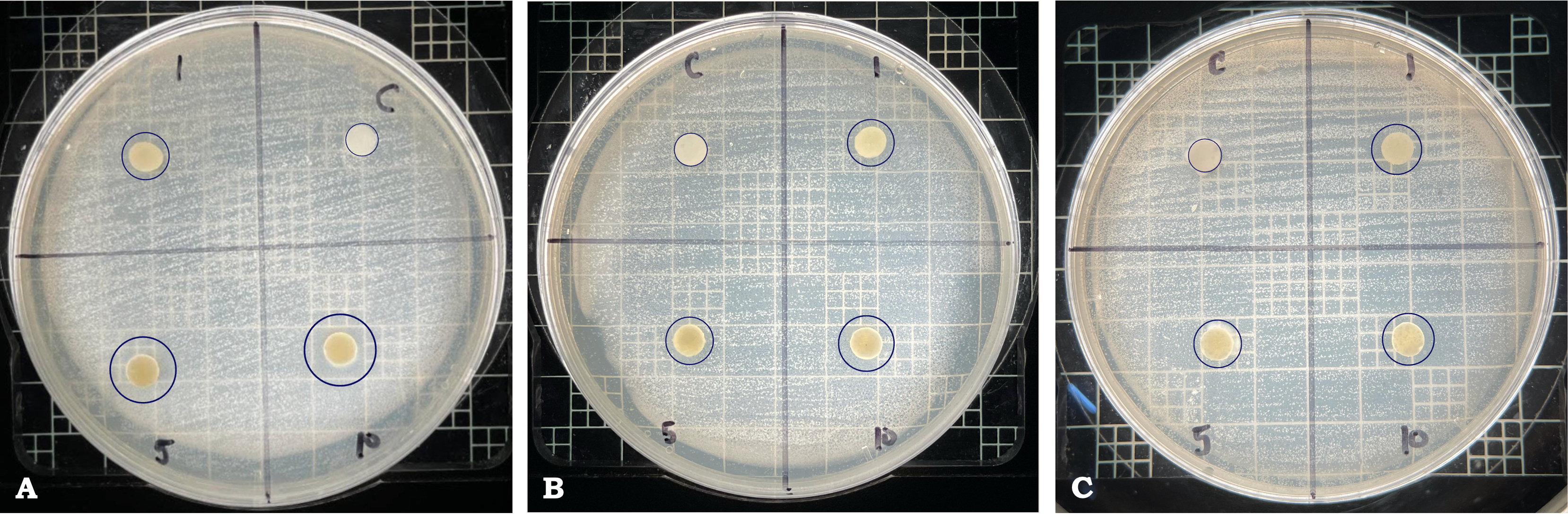

Methods: One control group and three experimental groups (composite containing 1%, 5% and 10% hydrated CaO) were utilized. Kirby-Bauer disk diffusion susceptibility test was conducted to evaluate the antibacterial property of the groups against gram-positive cocci. Furthermore, the properties of the composite resin, specifically the flexural strength, depth of cure, water sorption and solubility were also assessed to determine if these were compromised upon the addition of hydrated CaO. Shapiro-Wilk Test, Independent Samples t-Test and Mann-Whitney U test were used for data interpretation.

Results: The experimental groups with hydrated CaO significantly inhibited the growth of gram-positive cocci having p values of 0.015, 0.020 and 0.027 respectively when compared to the control group. These results favor the experimental groups. Moreover, there was no significant difference on the flexural strength, depth of cure, water sorption and solubility of the experimental groups and control group except that of the 5% concentration which had better polymerization (p=0.034) and the 10% concentration which was more water soluble (p=0.046).

Conclusions: It can be concluded that composite resin with hydrated CaO can be a promising restorative material with antibacterial efficacy and largely uncompromised properties. This innovation, alongside further research, can prevent the occurrence of failed restorations due to secondary caries formation.

Methods: One control group and three experimental groups (composite containing 1%, 5% and 10% hydrated CaO) were utilized. Kirby-Bauer disk diffusion susceptibility test was conducted to evaluate the antibacterial property of the groups against gram-positive cocci. Furthermore, the properties of the composite resin, specifically the flexural strength, depth of cure, water sorption and solubility were also assessed to determine if these were compromised upon the addition of hydrated CaO. Shapiro-Wilk Test, Independent Samples t-Test and Mann-Whitney U test were used for data interpretation.

Results: The experimental groups with hydrated CaO significantly inhibited the growth of gram-positive cocci having p values of 0.015, 0.020 and 0.027 respectively when compared to the control group. These results favor the experimental groups. Moreover, there was no significant difference on the flexural strength, depth of cure, water sorption and solubility of the experimental groups and control group except that of the 5% concentration which had better polymerization (p=0.034) and the 10% concentration which was more water soluble (p=0.046).

Conclusions: It can be concluded that composite resin with hydrated CaO can be a promising restorative material with antibacterial efficacy and largely uncompromised properties. This innovation, alongside further research, can prevent the occurrence of failed restorations due to secondary caries formation.