IADR Abstract Archives

Modified Wet Mechanochemical Method For Synthesis Of Optimized Bioceramic Nano-particles

Objectives: To introduce a new production technique for synthesis of bioceramic nano-particles with controlled and optimized physico-chemical properties considering biological, economic and ecological factors.

Methods: Nano hydroxyapatite (nHA) was produced from CaCO3 and CaHPO4 raw powders using a conventional (nHA-1) and modified (nHA-2) wet mechanochemical synthesis technique and controlled solid-state reaction. The production variables were modified from our last report (Ebrahimi et al. 2012) involving, 1) selection of smaller (3mm) and uniform milling balls, 2) increasing the wt.% of aqueous medium (H2O), 3) increasing total milling time (>48hrs), 4) modified powder refinement using double sieving (106 and 25 µm), and , 5) accurate control of sintering program (900°C at 300°C /hour heating rate). Crystallography (XRD), laser diffraction, scanning electron microscopy (SEM) and elemental analysis were used to characterize the powders and compare them to commercial nHA-F (nanoXIM, Fluidinova).

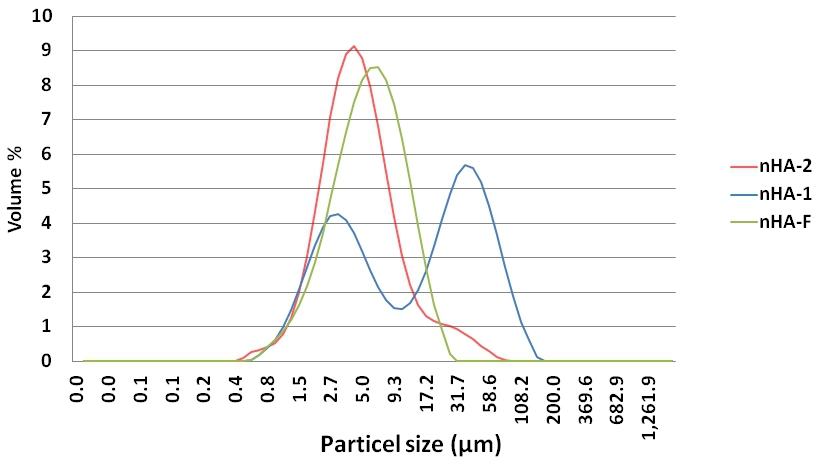

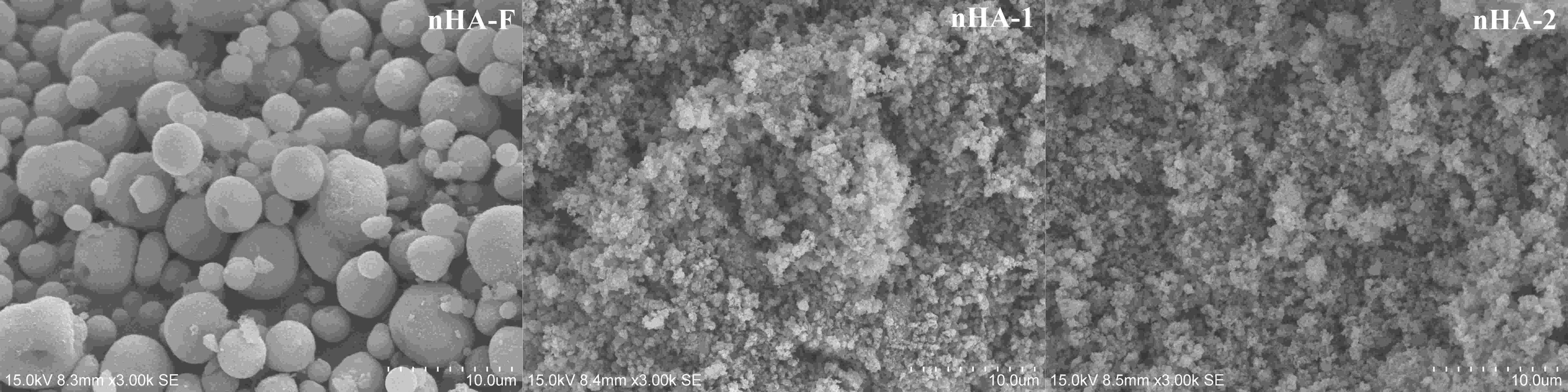

Results: XRD indexed major characteristic peaks of nHA, and two minor peaks corresponding to β-Ca3(PO4)2 in nHA-2 rendering the sample a biphasic nature. Both nHA-2 and nHA-F were detected as calcium deficient nHA. Compared to nHA-1 and nHA-F, the nHA-2 was detected with a higher Ca/P molar ratio displaying a narrower and sharper XRD peaks that indicate increased crystallinity, and reduced amorphous ratio and crystallite size (Table 1). In addition, the powder laser diffraction of nHA-2 exhibited a single peak which denote monomodal particle size distribution pattern of smaller dimension (Figure 1). This resulted in smaller and more homogenous particle agglomeration size which was obvious on SEM examination (Figure 2).

Conclusions: A simple, economic and ecologic (no byproducts), low-sintering synthesis method is introduced for production of nano-particles through careful control of processing variables and sintering program. This method allows production of biphasic bioceramics with customized physico-chemical properties that offer additional control of their biodegradation, bioactivity, and osteoinductivity. Such features may allow higher adsorption of growth factors, increased osteoblast adhesion, higher osteoblast activity, and more uniform cellular response with minimum toxicity for various tissue engineering applications.

Methods: Nano hydroxyapatite (nHA) was produced from CaCO3 and CaHPO4 raw powders using a conventional (nHA-1) and modified (nHA-2) wet mechanochemical synthesis technique and controlled solid-state reaction. The production variables were modified from our last report (Ebrahimi et al. 2012) involving, 1) selection of smaller (3mm) and uniform milling balls, 2) increasing the wt.% of aqueous medium (H2O), 3) increasing total milling time (>48hrs), 4) modified powder refinement using double sieving (106 and 25 µm), and , 5) accurate control of sintering program (900°C at 300°C /hour heating rate). Crystallography (XRD), laser diffraction, scanning electron microscopy (SEM) and elemental analysis were used to characterize the powders and compare them to commercial nHA-F (nanoXIM, Fluidinova).

Results: XRD indexed major characteristic peaks of nHA, and two minor peaks corresponding to β-Ca3(PO4)2 in nHA-2 rendering the sample a biphasic nature. Both nHA-2 and nHA-F were detected as calcium deficient nHA. Compared to nHA-1 and nHA-F, the nHA-2 was detected with a higher Ca/P molar ratio displaying a narrower and sharper XRD peaks that indicate increased crystallinity, and reduced amorphous ratio and crystallite size (Table 1). In addition, the powder laser diffraction of nHA-2 exhibited a single peak which denote monomodal particle size distribution pattern of smaller dimension (Figure 1). This resulted in smaller and more homogenous particle agglomeration size which was obvious on SEM examination (Figure 2).

Conclusions: A simple, economic and ecologic (no byproducts), low-sintering synthesis method is introduced for production of nano-particles through careful control of processing variables and sintering program. This method allows production of biphasic bioceramics with customized physico-chemical properties that offer additional control of their biodegradation, bioactivity, and osteoinductivity. Such features may allow higher adsorption of growth factors, increased osteoblast adhesion, higher osteoblast activity, and more uniform cellular response with minimum toxicity for various tissue engineering applications.