IADR Abstract Archives

Effect of Gingival Viscoelasticity on Dynamic Stress Distribution on Mandible

Objectives: Body tissues due to the presence of water and collagen fibers in response to external mechanical stimuli, are viscoelastic and have time-dependent behaviors. Reports showed that dentin during the treatment of root canal and the vessel wall during the onset of arteriosclerosis, due to the loss of fibrous compositions, cause decreases in viscoelastic property and as a result, change in the distribution of dynamic stress cause by chewing or physiological stress in each heart pulse will happen. In this study, gingival due to its viscoelastic property for surveying effects of different thicknesses on the extent and distribution of stress after implantation was modeled.

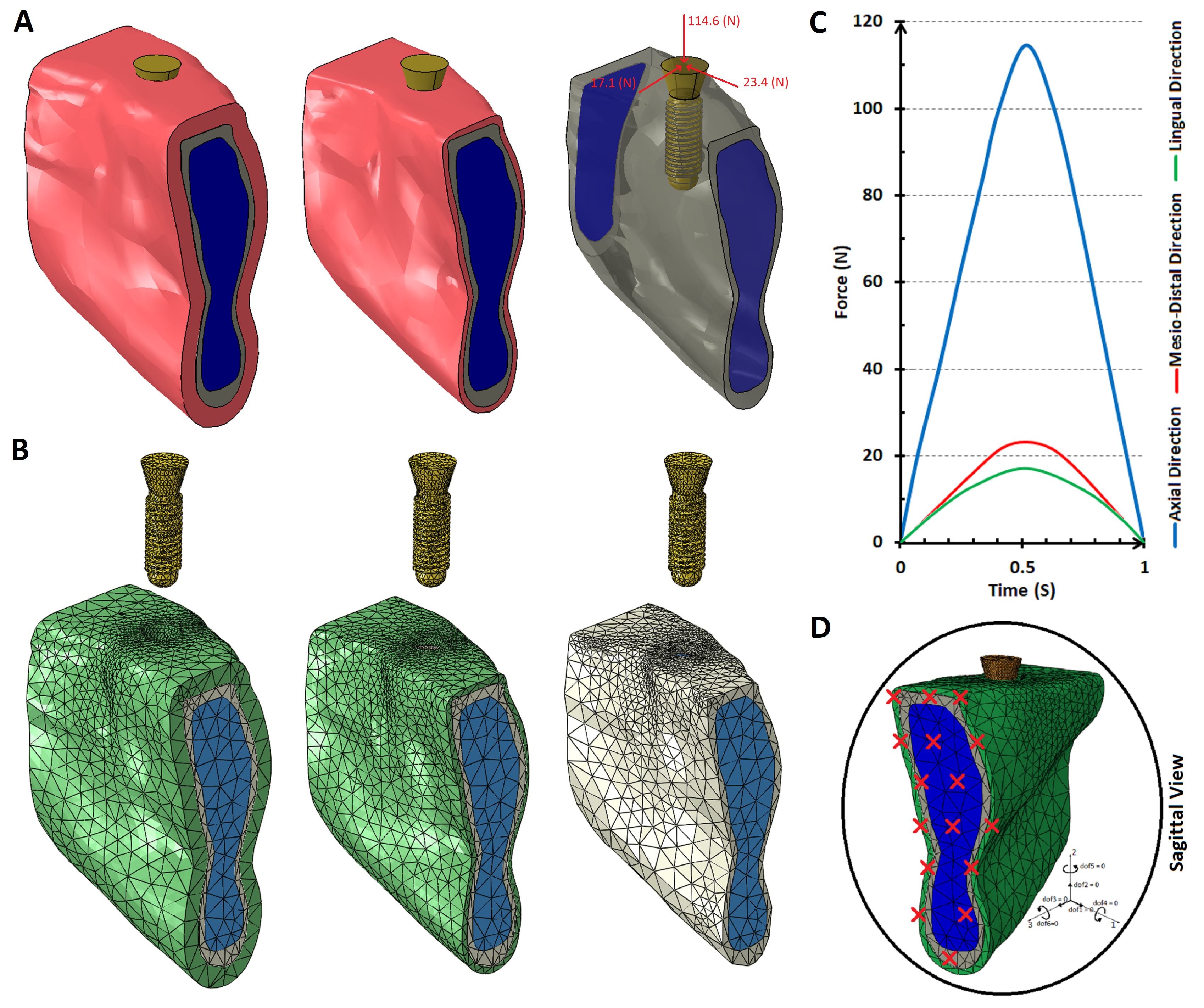

Methods: The three-dimensional model of cortical and trabecular mandibular bone and gingival obtained from CT scan using Mimics software. Three analyzes were modeled using FEM from gingival with 0, 0.8 and 2.4 mm thicknesses. The mechanical properties of mandibular bone and fixture, and the mechanical properties of gingival, considered respectively elastic and viscoelastic (Creep test data). The interaction between cortical bone with trabecular bone, cortical bone with gingival and fixture with bone was considered Tie, and the interaction between the gingival with fixture, was considered Contact with frictionless behavior. Loading of the implant in a lingual, a mesio-distal and an axial direction simulated. Time-dependent masticatory load, with varying amounts was applied in each direction.

Results: After applying six loading on the implant, it was determined that in the modeling with a thickness of 2.4 mm, the maximum stresses in the bone contact with the implant neck were 2% lower than the other models. There is no obvious difference between the no-gingival and gingival models with a thickness of 0.8 mm.

Conclusions: Although there is little difference in amount of stress between modeling with and without gingival, in the long-term the same amount can decrease the fatigue process and increase the lifetime of the implant. In addition, due to the no significant change in the stress value, it found in 0.8mm thickness modeling that the thinness of this tissue could reduce the lifetime of the implant.

Methods: The three-dimensional model of cortical and trabecular mandibular bone and gingival obtained from CT scan using Mimics software. Three analyzes were modeled using FEM from gingival with 0, 0.8 and 2.4 mm thicknesses. The mechanical properties of mandibular bone and fixture, and the mechanical properties of gingival, considered respectively elastic and viscoelastic (Creep test data). The interaction between cortical bone with trabecular bone, cortical bone with gingival and fixture with bone was considered Tie, and the interaction between the gingival with fixture, was considered Contact with frictionless behavior. Loading of the implant in a lingual, a mesio-distal and an axial direction simulated. Time-dependent masticatory load, with varying amounts was applied in each direction.

Results: After applying six loading on the implant, it was determined that in the modeling with a thickness of 2.4 mm, the maximum stresses in the bone contact with the implant neck were 2% lower than the other models. There is no obvious difference between the no-gingival and gingival models with a thickness of 0.8 mm.

Conclusions: Although there is little difference in amount of stress between modeling with and without gingival, in the long-term the same amount can decrease the fatigue process and increase the lifetime of the implant. In addition, due to the no significant change in the stress value, it found in 0.8mm thickness modeling that the thinness of this tissue could reduce the lifetime of the implant.