IADR Abstract Archives

Dimensional Accuracy and Storage Stability of Various 3D-Printed Dental Models

Objectives: To determine the accuracy of 3D printed dental models subjected to different storage conditions using six materials/printer systems.

Methods: Three full arch models with a prepared crown were designed using 3Shape software. Each type of model was printed every week for a 4 week period using six resin materials and various digital light processing printers: DPR 10 resin by a DLP-A printer, Model HP UV 2.0 resin with a DLP-B, MED610 resin with Polyjet-A and DLP-C printers , E-Model Light DLP resin with a DLP-D printer, VeriModel resin with a DLP-E printer with a standard layer thickness of 50 μm. All models were scanned using inEos X5 lab scanner once received after printing, then the full arch models were randomly assigned into 3 groups of storage condition, LT: cold environment (4 ± 1°C), HT: hot and dry environment (50 ± 2°C), and RT: room temperature (25 ± 2°C) serving as the control. Each group was kept under the designated thermal-static conditions and were scanned after one week. The generated STL files were imported into a 3D inspection software for comparison with the original STL file. In-tolerance percentage with a tolerance of 30, 50, 75 and 100 μm and the deviation RMS were obtained and analyzed. Least square mean linear regression was performed using JMP Pro 15 to identify the significant effects (α=0.05).

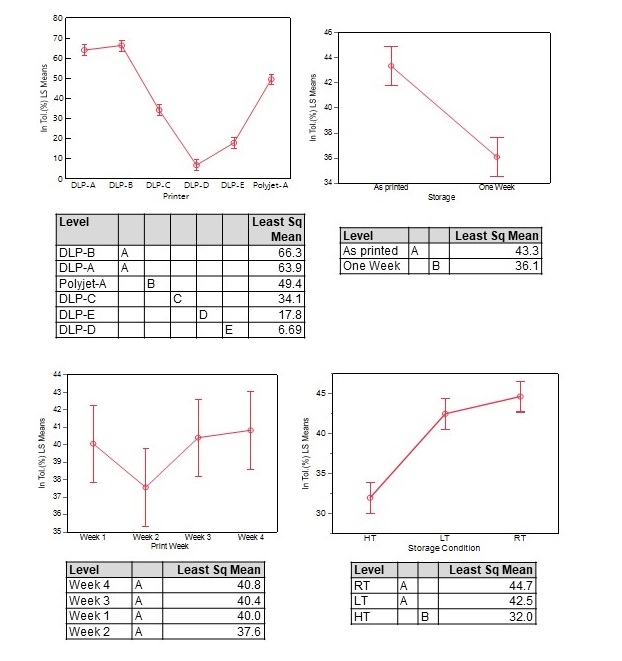

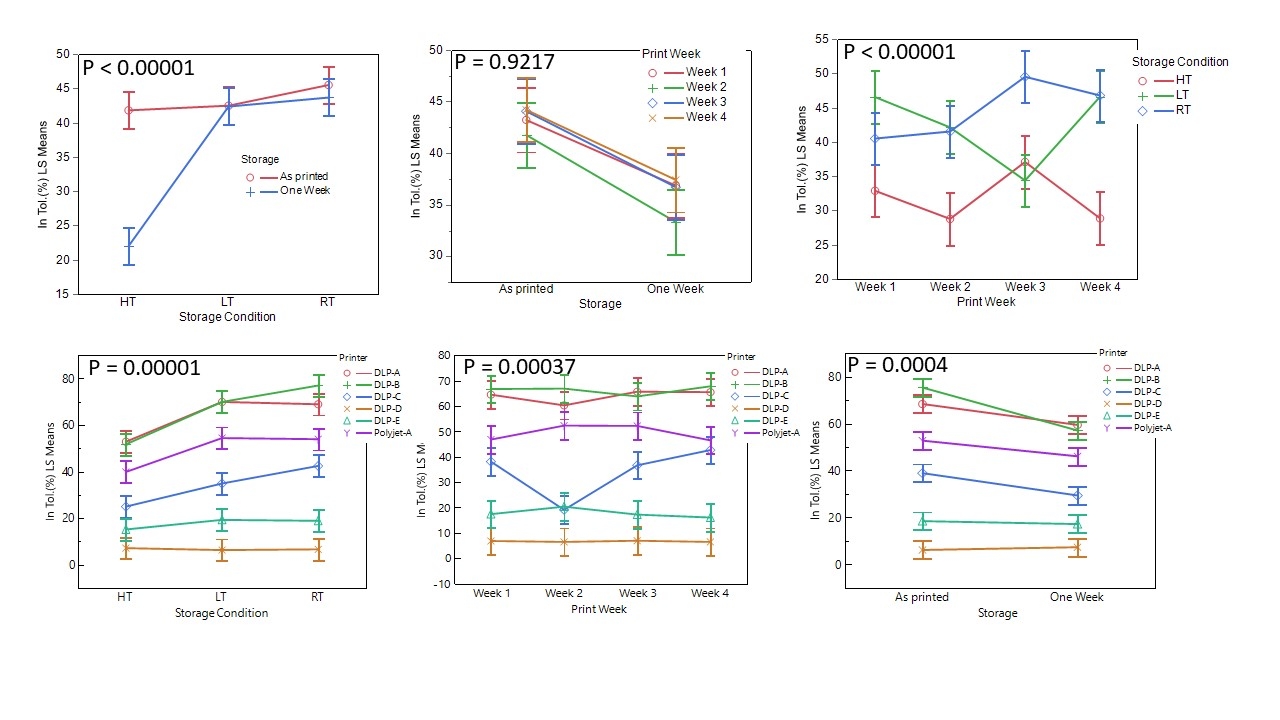

Results: Table 1 showed the effect summary of the main effects of printer, printing week, storage, and storage condition, and their interactions. Fig. 1 and Fig. 2 showed the dominate effects were the printer type and storage condition.

Conclusions: The model deviations were affected by storage condition and the resin used. High temperature storage showed worse stability compared to low temperature and room temperatures.

Methods: Three full arch models with a prepared crown were designed using 3Shape software. Each type of model was printed every week for a 4 week period using six resin materials and various digital light processing printers: DPR 10 resin by a DLP-A printer, Model HP UV 2.0 resin with a DLP-B, MED610 resin with Polyjet-A and DLP-C printers , E-Model Light DLP resin with a DLP-D printer, VeriModel resin with a DLP-E printer with a standard layer thickness of 50 μm. All models were scanned using inEos X5 lab scanner once received after printing, then the full arch models were randomly assigned into 3 groups of storage condition, LT: cold environment (4 ± 1°C), HT: hot and dry environment (50 ± 2°C), and RT: room temperature (25 ± 2°C) serving as the control. Each group was kept under the designated thermal-static conditions and were scanned after one week. The generated STL files were imported into a 3D inspection software for comparison with the original STL file. In-tolerance percentage with a tolerance of 30, 50, 75 and 100 μm and the deviation RMS were obtained and analyzed. Least square mean linear regression was performed using JMP Pro 15 to identify the significant effects (α=0.05).

Results: Table 1 showed the effect summary of the main effects of printer, printing week, storage, and storage condition, and their interactions. Fig. 1 and Fig. 2 showed the dominate effects were the printer type and storage condition.

Conclusions: The model deviations were affected by storage condition and the resin used. High temperature storage showed worse stability compared to low temperature and room temperatures.