IADR Abstract Archives

Effects of Sintering Protocols on Microstructure and Strength of Zirconia

Objectives: Identify the effects of different sintering protocols on grain size and mechanical properties of different zirconia blocks

Methods: Four types of zirconia CAD/CAM blocks were used in this study: InCoris TZI A1, InCoris TZI A3.5, InCoris TZI A4, Vita In-Ceram YZ. All the blocks were sectioned into 20 rectangular bars per material for post fire dimensions 4×3×13 mm and sintered using two different furnaces with different firing protocols: Vita Zyrcomat using conventional zirconia firing protocol (1530°C 2h, total ~6h), and Sirona inFire HTC Speed using SpeedFire firing protocol (1540°C 30min, total ~1.5h)

After sintering the blocks, flexural strength of the all the specimens were measured using Instron 5565A in three-point bending according to ISO 6872. Scanning Electron Microscopy (SEM) was further used to measure the grain size of obtained samples.

Data were analyzed by JMP Pro 13 software using one-way ANOVA post hoc Tukey test to detect the significant difference (α= 0.05) in flexural strength and grain size. Also, Weibull distribution was used to describe variability in the tested material strengths.

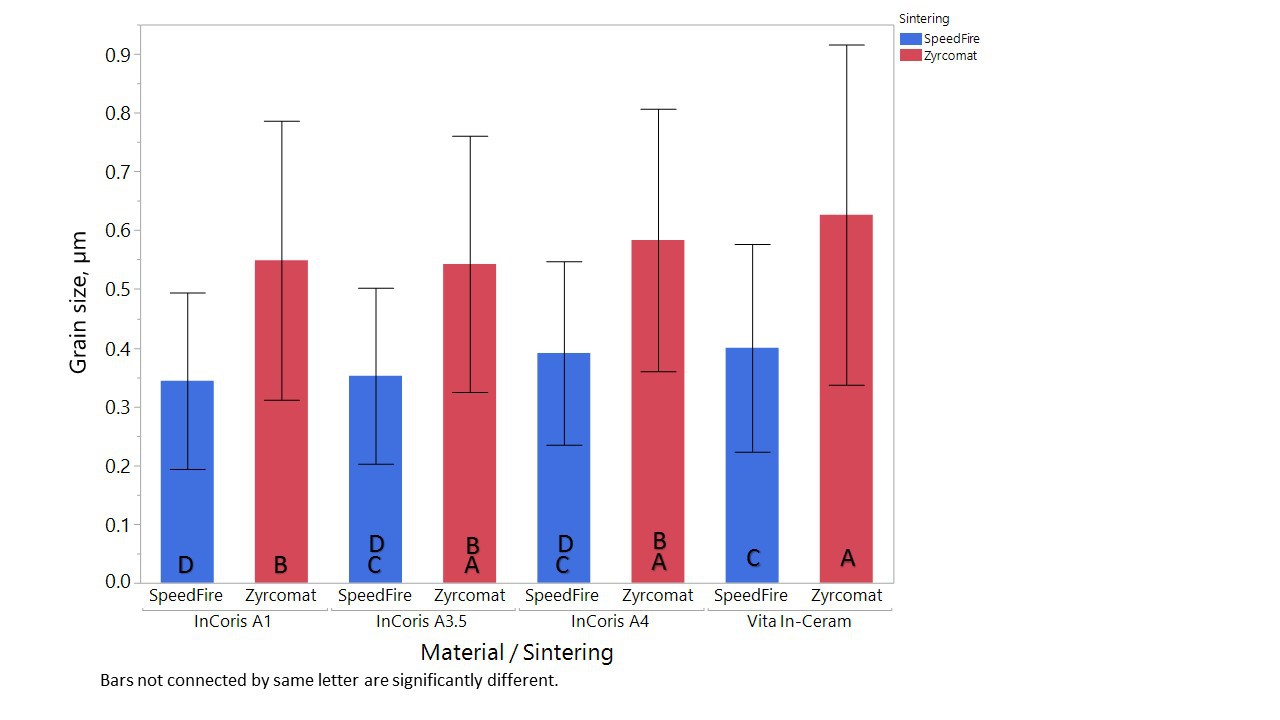

Results: The mean grain size for zirconia sintered with the conventional protocol and SpeedFire sintering protocol are shown in Figure 1. Flexural strength and Weibull modulus of tested groups are shown in Table 1.

Conclusions: Sintering Zirconia using conventional sintering protocol results in growing larger crystals in compare to SpeedFire sintering protocol. Vita In-Ceram YZ and InCoris TZI A4 showed significant larger grain size than InCoris TZI A1 and InCoris TZI A3.5. However, the differences in grain size did not cause any significant changes in strength of the materials.

Methods: Four types of zirconia CAD/CAM blocks were used in this study: InCoris TZI A1, InCoris TZI A3.5, InCoris TZI A4, Vita In-Ceram YZ. All the blocks were sectioned into 20 rectangular bars per material for post fire dimensions 4×3×13 mm and sintered using two different furnaces with different firing protocols: Vita Zyrcomat using conventional zirconia firing protocol (1530°C 2h, total ~6h), and Sirona inFire HTC Speed using SpeedFire firing protocol (1540°C 30min, total ~1.5h)

After sintering the blocks, flexural strength of the all the specimens were measured using Instron 5565A in three-point bending according to ISO 6872. Scanning Electron Microscopy (SEM) was further used to measure the grain size of obtained samples.

Data were analyzed by JMP Pro 13 software using one-way ANOVA post hoc Tukey test to detect the significant difference (α= 0.05) in flexural strength and grain size. Also, Weibull distribution was used to describe variability in the tested material strengths.

Results: The mean grain size for zirconia sintered with the conventional protocol and SpeedFire sintering protocol are shown in Figure 1. Flexural strength and Weibull modulus of tested groups are shown in Table 1.

Conclusions: Sintering Zirconia using conventional sintering protocol results in growing larger crystals in compare to SpeedFire sintering protocol. Vita In-Ceram YZ and InCoris TZI A4 showed significant larger grain size than InCoris TZI A1 and InCoris TZI A3.5. However, the differences in grain size did not cause any significant changes in strength of the materials.