IADR Abstract Archives

Mechanically Robust 3D-Printed Composites Achieved via Extrusion-Based Direct-ink Writing

Objectives: The study aims to evaluate the mechanical strength and anisotropy of the highly filled resin composite beams, produced by direct-ink writing (DIW) 3D printing technology.

Methods: An experimental 3-axis DIW printer was developed to enable light-assisted printing using a clinically approved thermo-viscous dental composite (VisCalor bulk with 83wt% inorganic filler, VOCO). The samples were printed layerwise in the Z-direction and immediately post-cured after printing using a hand-held curing light for 60s (Bluephase style, Ivoclar Vivadent, with irradiance>1000 mW/cm2). The DIW-printed beams were tested by three-point bending until fracture following ISO 4049. To evaluate mechanical anisotropy, the printed beams were loaded either perpendicularly (DIW-Perp) or parallelly (DIW-Para) to the Z-layers (n=35 for both groups, with crosshead speed 1 mm/min). For comparison, bulk molded then light-cured nanocomposite samples (unheated VisCalor-bulk and GrandioSO with 89wt% filler, VOCO) were tested using the same protocol.

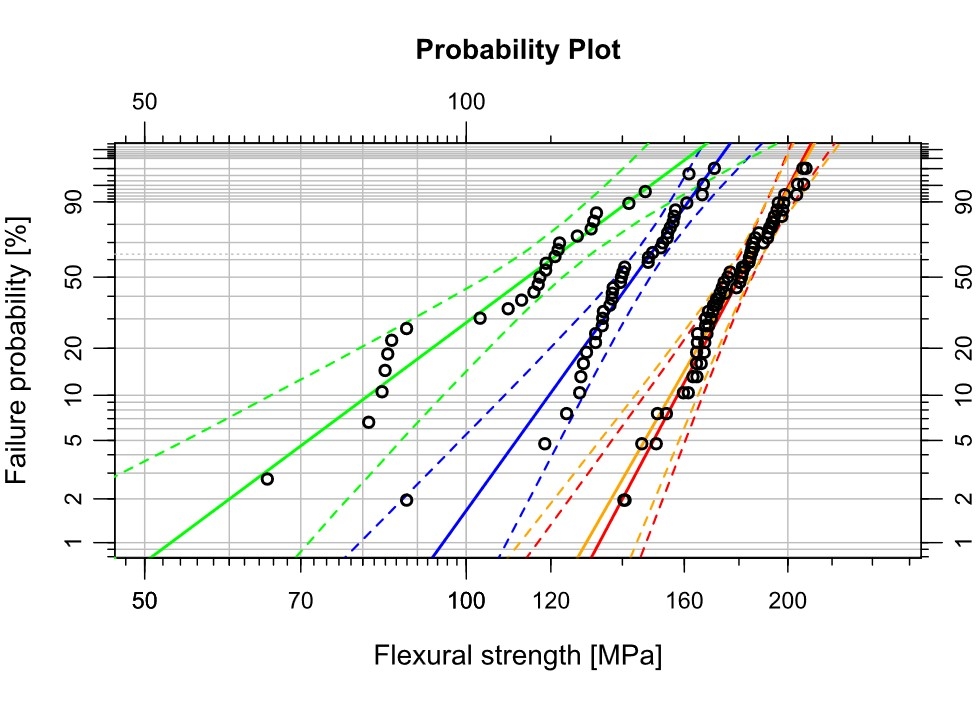

Results: Weibull analysis on the fracture strength revealed that both DIW-Perp and DIW-Para samples had similar characteristic strengths (185.5[180.8, 190.4] and 185.2[180.0, 190.6] MPa, respectively with 95% CI). Furthermore, DIW-printed VisCalor samples exhibited moderate mechanical reliability (Weibull modulus of 13.5 and 12.2 for DIW-Perp and DIW-Para, respectively). On the other hand, conventionally molded samples had inferior characteristic strength (VisCalor-bulk: 122.2[113.4, 131.6], GrandioSO: 148.7[143.9, 153.7] MPa) and reliability (Weibull modulus of 5.6 and 10.6, respectively for VisCalor-bulk and GrandioSO). SEM images on the fractured DIW samples showed seamless inter-layer integration without internal voids, accounting for their mechanical robustness.

Conclusions: DIW-printed samples exhibit ideal strength, high reliability, and minimal anisotropy. Furthermore, their mechanical performance was significantly better than that of the conventionally fabricated samples made of well-accepted nanocomposites. Considering the DIW technology's zero-leftover and minimal waste nature, along with the time-efficient and energy-efficient post-curing regime, this study opens a promising path to the on-demand production of high-performance dental restorations with enhanced sustainability.

Methods: An experimental 3-axis DIW printer was developed to enable light-assisted printing using a clinically approved thermo-viscous dental composite (VisCalor bulk with 83wt% inorganic filler, VOCO). The samples were printed layerwise in the Z-direction and immediately post-cured after printing using a hand-held curing light for 60s (Bluephase style, Ivoclar Vivadent, with irradiance>1000 mW/cm2). The DIW-printed beams were tested by three-point bending until fracture following ISO 4049. To evaluate mechanical anisotropy, the printed beams were loaded either perpendicularly (DIW-Perp) or parallelly (DIW-Para) to the Z-layers (n=35 for both groups, with crosshead speed 1 mm/min). For comparison, bulk molded then light-cured nanocomposite samples (unheated VisCalor-bulk and GrandioSO with 89wt% filler, VOCO) were tested using the same protocol.

Results: Weibull analysis on the fracture strength revealed that both DIW-Perp and DIW-Para samples had similar characteristic strengths (185.5[180.8, 190.4] and 185.2[180.0, 190.6] MPa, respectively with 95% CI). Furthermore, DIW-printed VisCalor samples exhibited moderate mechanical reliability (Weibull modulus of 13.5 and 12.2 for DIW-Perp and DIW-Para, respectively). On the other hand, conventionally molded samples had inferior characteristic strength (VisCalor-bulk: 122.2[113.4, 131.6], GrandioSO: 148.7[143.9, 153.7] MPa) and reliability (Weibull modulus of 5.6 and 10.6, respectively for VisCalor-bulk and GrandioSO). SEM images on the fractured DIW samples showed seamless inter-layer integration without internal voids, accounting for their mechanical robustness.

Conclusions: DIW-printed samples exhibit ideal strength, high reliability, and minimal anisotropy. Furthermore, their mechanical performance was significantly better than that of the conventionally fabricated samples made of well-accepted nanocomposites. Considering the DIW technology's zero-leftover and minimal waste nature, along with the time-efficient and energy-efficient post-curing regime, this study opens a promising path to the on-demand production of high-performance dental restorations with enhanced sustainability.