IADR Abstract Archives

Synthesis and Characterization of a Lithium Disilicate Ceramic by Robocasting.

Objectives: The objective of this study was to evaluate the viability of manufacturing a Lithium disilicate ceramic by robocasting (direct inkjet writing), testing it mechanically and analyzing its microstructure.

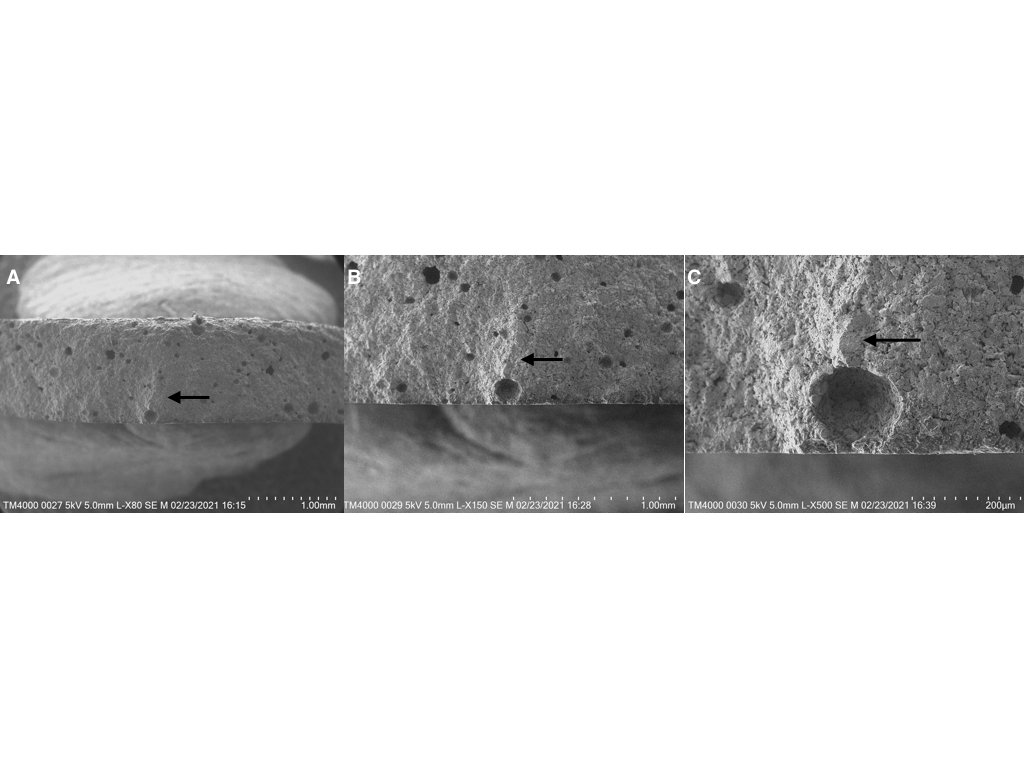

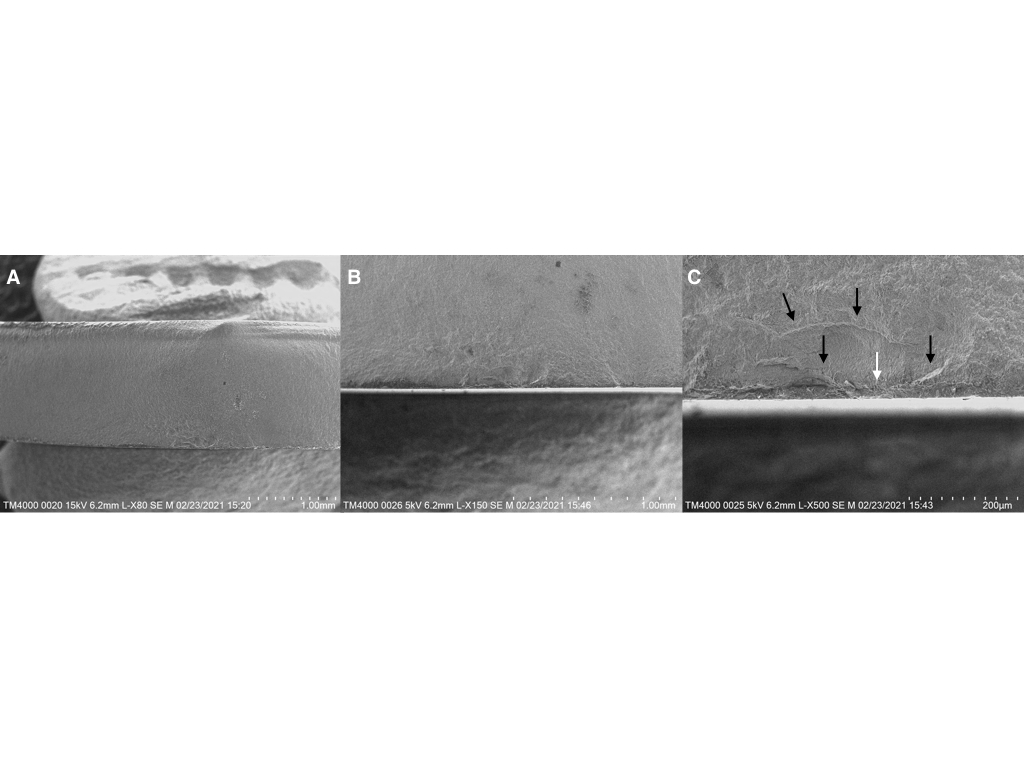

Methods: The experimental groups (n=30) were divided as: AR (additive/robocasting) and MS (milled/subtractive). For AR group, a formulated ink was prepared from a Lithium disilicate ceramic powder. Then, a disc shape digital model was created in a software and then printed with the fabricated ink using a 3D printer. For MS, the discs were fabricated from pre-crystallized ceramic blocks using a precision sectioning saw. All specimens were crystallized at 840° C, reaching final dimensions of approximately 12mm x 1.2mm. The specimens were submitted to 3-point flexural strength test (BFS) (n=30) in a universal testing machine using a load cell of 500N, and the load values were recorded in the moment of fracture. Scanning electron microscopy (SEM) was used to take representative fractographic images to analyze the fracture origin and the materials porosity. The specimens were submitted to Vickers hardness test (n=5) in a hardness testing machine, with 5 indentations in each specimen (load of 1Kgf/15s) in points spaced by 500µm. X-ray diffractometry (XRD) (n=1) was used for chemical analysis of the crystalline phase of the specimens.

Results: For BFS and Vickers, AR group had lower values (120.02 ± 33.91 MPa and 4.07 ± 0.30 GPa, respectively) than MS group (325.09 ± 63.98 MPa and 5.63 ± 0.14 GPa, respectively). For XRD analysis, AR showed lower Lithium metasilicate to Lithium disilicate conversion than MS. SEM images showed that AR microstructure had more porosity than MS.

Conclusions: The viability of the fabrication of a Lithium disilicate ceramic by robocasting was demonstrated. However, it presented worse mechanical performance, what could be explained by lower formation of Lithium disilicate crystals and a higher porosity in the microstructure.

Methods: The experimental groups (n=30) were divided as: AR (additive/robocasting) and MS (milled/subtractive). For AR group, a formulated ink was prepared from a Lithium disilicate ceramic powder. Then, a disc shape digital model was created in a software and then printed with the fabricated ink using a 3D printer. For MS, the discs were fabricated from pre-crystallized ceramic blocks using a precision sectioning saw. All specimens were crystallized at 840° C, reaching final dimensions of approximately 12mm x 1.2mm. The specimens were submitted to 3-point flexural strength test (BFS) (n=30) in a universal testing machine using a load cell of 500N, and the load values were recorded in the moment of fracture. Scanning electron microscopy (SEM) was used to take representative fractographic images to analyze the fracture origin and the materials porosity. The specimens were submitted to Vickers hardness test (n=5) in a hardness testing machine, with 5 indentations in each specimen (load of 1Kgf/15s) in points spaced by 500µm. X-ray diffractometry (XRD) (n=1) was used for chemical analysis of the crystalline phase of the specimens.

Results: For BFS and Vickers, AR group had lower values (120.02 ± 33.91 MPa and 4.07 ± 0.30 GPa, respectively) than MS group (325.09 ± 63.98 MPa and 5.63 ± 0.14 GPa, respectively). For XRD analysis, AR showed lower Lithium metasilicate to Lithium disilicate conversion than MS. SEM images showed that AR microstructure had more porosity than MS.

Conclusions: The viability of the fabrication of a Lithium disilicate ceramic by robocasting was demonstrated. However, it presented worse mechanical performance, what could be explained by lower formation of Lithium disilicate crystals and a higher porosity in the microstructure.