IADR Abstract Archives

Comparison of Flexural Strength of 3D-Printed and CAD/CAM Denture Base Materials

Objectives: Evaluate the flexural strength, flexural modulus and modulus of resilience among various digital denture base materials with different fabrication technology.

Methods: The materials included in the study were "lucitone 199 Denture Base Disc Original (Dentsply Sirona), AvaDent The materials included in the study were Lucitone 199 Denture Base Disc Original (Dentsply Sirona), AvaDent Denture Base Puck Original (AvaDent), KeyMill Denture Base Disc Pink (Keystone), Lucitone Digital Print 3D denture base (Sirona), Formlabs Denture Base OP resin (Formlabs), Dentca denture base II original pink (Detnca). A total of 36 rectangular bar specimens of each materials were prepared with a dimension of 4mm Χ 4mm Χ 25mm in the following manner: the CAD/CAM blocks were sectioned into a grid of rectangular bars using Buehler Isomet 5000 Precision Saw. The 3D printed materials were desgined and printed into desired bar dimensions following the manufacturers' recommendation of printing and post curing instructions. The specimens were divided into 3 subgroups: one control and two treatment groups, cyclic loading fatigue and thermocycling. The control specimens were stored in distilled water at 37 ± 1°C for 7 days. The fatigued group recieved 60% of the static load to failure on the materials for 200,000 cycles in water bath. The thermocycled group were subjected to 5,000 thermal cycling procedures between 5°C and 55°C with 30s dwelling time. The three-point flexural strength test was conducted using the Instron 5566A universal testing machine. The data were analyzed using one-way ANOVA followed by Tukey's HSD post-hoc test (α=0.05).

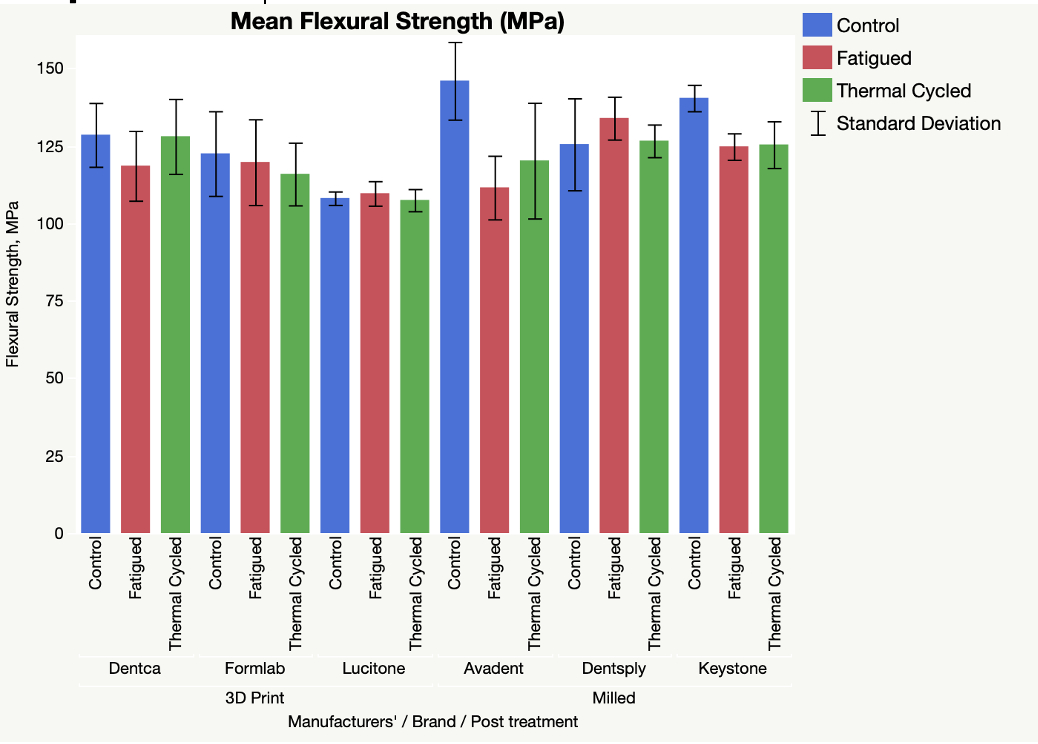

Results: The results are shown in Figure 1 and Table 1.

Conclusions: Generally, CAD/CAM PMMA denture base materials exhibited signifcant higher flexural strength and flexural modulus. CAD/CAM dentures are expcted to be more durable.

Methods: The materials included in the study were "lucitone 199 Denture Base Disc Original (Dentsply Sirona), AvaDent The materials included in the study were Lucitone 199 Denture Base Disc Original (Dentsply Sirona), AvaDent Denture Base Puck Original (AvaDent), KeyMill Denture Base Disc Pink (Keystone), Lucitone Digital Print 3D denture base (Sirona), Formlabs Denture Base OP resin (Formlabs), Dentca denture base II original pink (Detnca). A total of 36 rectangular bar specimens of each materials were prepared with a dimension of 4mm Χ 4mm Χ 25mm in the following manner: the CAD/CAM blocks were sectioned into a grid of rectangular bars using Buehler Isomet 5000 Precision Saw. The 3D printed materials were desgined and printed into desired bar dimensions following the manufacturers' recommendation of printing and post curing instructions. The specimens were divided into 3 subgroups: one control and two treatment groups, cyclic loading fatigue and thermocycling. The control specimens were stored in distilled water at 37 ± 1°C for 7 days. The fatigued group recieved 60% of the static load to failure on the materials for 200,000 cycles in water bath. The thermocycled group were subjected to 5,000 thermal cycling procedures between 5°C and 55°C with 30s dwelling time. The three-point flexural strength test was conducted using the Instron 5566A universal testing machine. The data were analyzed using one-way ANOVA followed by Tukey's HSD post-hoc test (α=0.05).

Results: The results are shown in Figure 1 and Table 1.

Conclusions: Generally, CAD/CAM PMMA denture base materials exhibited signifcant higher flexural strength and flexural modulus. CAD/CAM dentures are expcted to be more durable.