IADR Abstract Archives

Effect of Different Polymers on Interpenetrating Phase Ceramic Matrix Composites

Objectives: To determine the effects of different polymers on the optical properties, physical properties, and mechanical properties of ceramic-polymer interpenetrating phase composites.

Methods: The ceramic discs were prepared by slip casting technique using alumina powder (Almatis A16SG) referred as group A and low fusing Vita feldspathic porcelain powder with binder referred as group B. Both groups were partially sintered at 1250 C for 4 hours with ramp rate 10 C/min (Group A) and 960 C for 30 minutes with ramp rate at 40 C/min (Group B). Both groups were polished to produce 2 mm-thick discs. The polished discs in each group were randomly divided into 2 subgroups. After silane infiltration, the first subgroup was infiltrated with a resin mixture of urethane dimethacrylate (UDMA) with triethylene glycol dimethacrylate (TEGDMA) (U1T1) while the second one was infiltrated with a resin mixture of UDMA with triethylene glycol divinylbenzyl ether (TEG-DVBE) (U1V1). After infiltration, the discs were heat cured at 90 C under pressure for 10 hours (U1T1 group) and for 24 hours (U1V1 group). The degree of conversion of both polymers was measured using an FTIR spectrophotometer and specimen density was evaluated. The optical properties including contrast ratio, transparency parameter, and visible light transmission were measured using a spectrophotometer (Ci7600, X-Rite). FE-SEM and EDS were used to analyze for morphology and matrix interconnectivity. Biaxial flexural strength was measured by universal testing machine (Instron 5566A) Analysis of variance (ANOVA) followed by Tukey’s multiple-comparison test (p < 0.05) was used to analyze the density and optical properties using JMP.

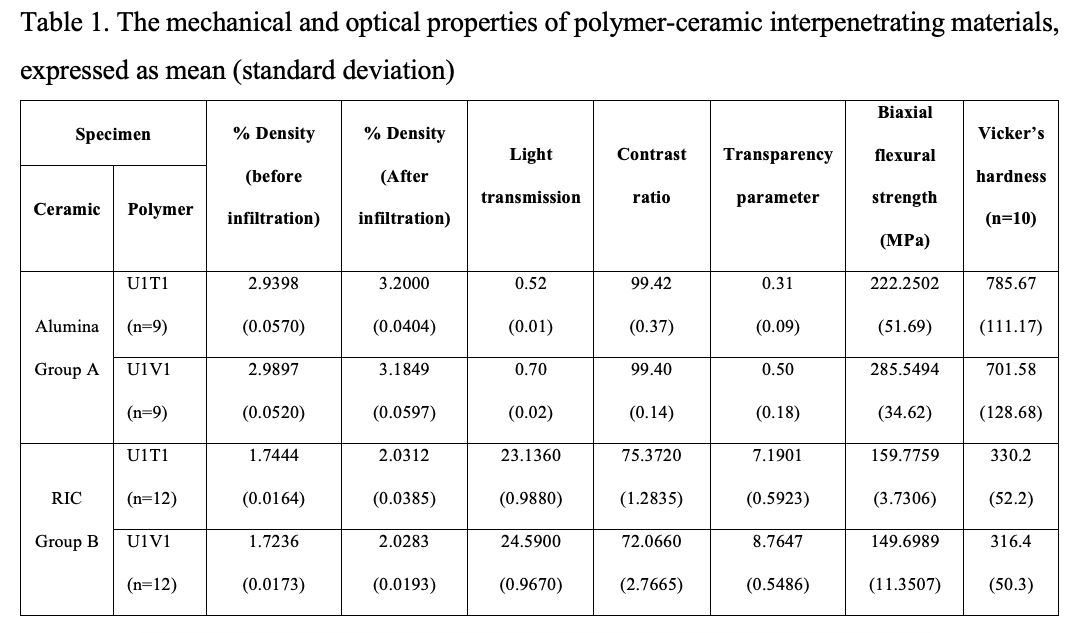

Results: The average degree of conversion was 95.6±1.6% for U1V1 and 80.4±2.3% for U1T1. The average and standard deviation of % density, light transmission, transparent parameter, and contrast ratio, and biaxial flexural strength of different interpenetrating ceramic matrix are shown in Table 1.

Conclusions: Polymer-ceramic interpenetrating materials made from U1V1 monomer showed similar mechanical and optical properties as traditional U1T1 monomer mix.

Methods: The ceramic discs were prepared by slip casting technique using alumina powder (Almatis A16SG) referred as group A and low fusing Vita feldspathic porcelain powder with binder referred as group B. Both groups were partially sintered at 1250 C for 4 hours with ramp rate 10 C/min (Group A) and 960 C for 30 minutes with ramp rate at 40 C/min (Group B). Both groups were polished to produce 2 mm-thick discs. The polished discs in each group were randomly divided into 2 subgroups. After silane infiltration, the first subgroup was infiltrated with a resin mixture of urethane dimethacrylate (UDMA) with triethylene glycol dimethacrylate (TEGDMA) (U1T1) while the second one was infiltrated with a resin mixture of UDMA with triethylene glycol divinylbenzyl ether (TEG-DVBE) (U1V1). After infiltration, the discs were heat cured at 90 C under pressure for 10 hours (U1T1 group) and for 24 hours (U1V1 group). The degree of conversion of both polymers was measured using an FTIR spectrophotometer and specimen density was evaluated. The optical properties including contrast ratio, transparency parameter, and visible light transmission were measured using a spectrophotometer (Ci7600, X-Rite). FE-SEM and EDS were used to analyze for morphology and matrix interconnectivity. Biaxial flexural strength was measured by universal testing machine (Instron 5566A) Analysis of variance (ANOVA) followed by Tukey’s multiple-comparison test (p < 0.05) was used to analyze the density and optical properties using JMP.

Results: The average degree of conversion was 95.6±1.6% for U1V1 and 80.4±2.3% for U1T1. The average and standard deviation of % density, light transmission, transparent parameter, and contrast ratio, and biaxial flexural strength of different interpenetrating ceramic matrix are shown in Table 1.

Conclusions: Polymer-ceramic interpenetrating materials made from U1V1 monomer showed similar mechanical and optical properties as traditional U1T1 monomer mix.