IADR Abstract Archives

Influence of Sintering Conditions on Zirconia Properties

Objectives: ZrO2 based ceramic material has been intensively studied due to their excellent mechanical properties. ZrO2 has been used as a dental ceramic material as a substitute to the usual prosthetic metallic structure due to their good biocompatibility, clinical longevity and high mechanical strength. Studies have demonstrated that the good mechanical properties of this class of material is associated to martensitic transformation in the zirconium oxide grains that occurs into the ceramic material during the mechanical loading.

Several dental industries have developed the production of zirconium oxide bodies through the CAD/CAM systems. This study has the objective to investigate the mechanical strength and microstructure of zirconium oxide with yttria sintered at different temperature and time.

Methods: The material used in this work was collected directly from Cercon (Dentsply). Six zirconium oxide blocks were cut and separated in three groups (G1, G2 and G3). The sintering conditions used in this work are shown in table 1. The sintered materials were characterized by Flexural Strength, Vickers hardness, Fracture Toughness, Density and Grain Size. The test of flexural strength used in this study was four points bending, whose results are more sensitive to defective surface when compared with biaxial test.

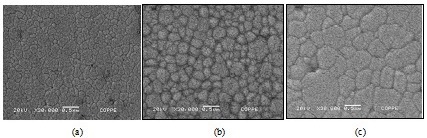

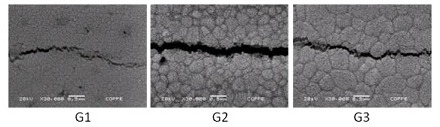

Results: The results show that the properties are strongly dependent on the sintering conditions (Table 2). Figure 1 illustrates the micrographs of G1, G2 and G3 when thermally etched at different temperatures. Images with examples of fracture origins can be shown in Figure 2.

Conclusions: Irrespective of temperature variety and sintering time, the three groups investigated in this work combine good strength and fracture toughness and high hardness comparable with other commercial zirconia materials. The sintering conditions have showed the control of physical and mechanical properties. The microstructure has showed to be homogeneous and no presence of large pores was found. Zirconia material displays homogeneous and small grain size distribution.

Several dental industries have developed the production of zirconium oxide bodies through the CAD/CAM systems. This study has the objective to investigate the mechanical strength and microstructure of zirconium oxide with yttria sintered at different temperature and time.

Methods: The material used in this work was collected directly from Cercon (Dentsply). Six zirconium oxide blocks were cut and separated in three groups (G1, G2 and G3). The sintering conditions used in this work are shown in table 1. The sintered materials were characterized by Flexural Strength, Vickers hardness, Fracture Toughness, Density and Grain Size. The test of flexural strength used in this study was four points bending, whose results are more sensitive to defective surface when compared with biaxial test.

Results: The results show that the properties are strongly dependent on the sintering conditions (Table 2). Figure 1 illustrates the micrographs of G1, G2 and G3 when thermally etched at different temperatures. Images with examples of fracture origins can be shown in Figure 2.

Conclusions: Irrespective of temperature variety and sintering time, the three groups investigated in this work combine good strength and fracture toughness and high hardness comparable with other commercial zirconia materials. The sintering conditions have showed the control of physical and mechanical properties. The microstructure has showed to be homogeneous and no presence of large pores was found. Zirconia material displays homogeneous and small grain size distribution.